Processing Capabilities

Gould Alloys' state-of-the-art facilities incorporate cutting-edge technology tailored to offer maximum added value to our customers.

Our facilities enable customers to procure materials that are 'near to net weight' and 'near to size,' ensuring optimal efficiency and cost-effectiveness.

What can you expect when you order from Gould?

We offer a wide range of added-value operations, from cutting to first-stage precision machining. Our in-house capabilities streamline processes, ensuring efficiency, and our rigorous inspection ensures compliance. Our main capabilities include cutting, full billet preparation, milling, drilling, tapping, counter-boring, turning, and grinding, all within our modern facilities.

Our primary focus is providing our customers with cost-effective and time-efficient solutions that enhance their manufacturing efficiency. Incorporating pre-machining before delivery has the potential to eliminate up to 90 percent of the metal. This results in increased production efficiency and cost-effectiveness for our customers, enabling them to concentrate on producing high-value finished products; we streamline the process.

All operations are strictly controlled to ensure our customer expectations can be met while maintaining product quality.

We operate automatic and semi-automatic circular and band saws, enabling ultimate flexibility when cutting any metal in any quantity. Bars can be supplied cut in half to make handling easier, cut to matrix (full bars cut to an equal length multiple) or cut into billets or discs. With multiple saws offering various capabilities, we can offer the following:

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal capability

- Up to 400mm diameter

- Cutting tolerances of +/- 1.0mm

- Electronically controlled Dot Peen hard stamping

- Full lot traceability

- Bar deburring

- Chamfering of bar ends

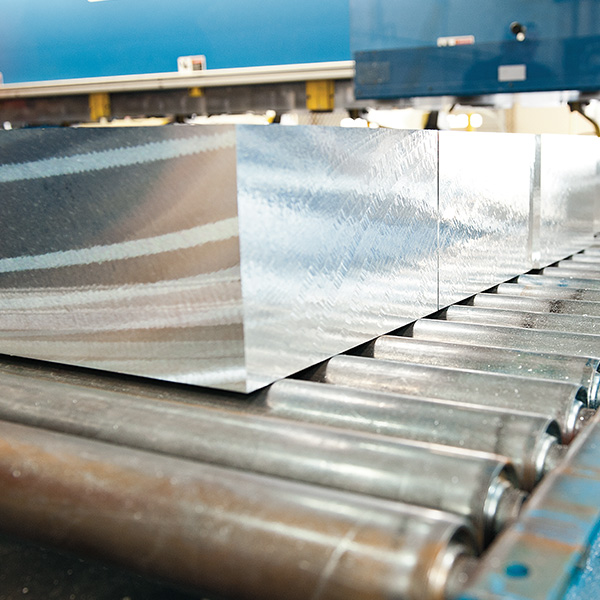

We offer multiple types of plate saws with various capabilities from our dedicated plate centre of excellence, allowing us to provide:

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal capability

- Cutting of plate up to 300mm thickness

- Cut length of up to 4000mm

- Cutting tolerances of +/-1.0mm

- Cut plate nesting to maximise utilisation

- Profiled shapes as well as standard rectangles

- Electronically controlled Dot Peen hard stamping

- Full lot traceability

Pushing the boundaries of our multiple water jets’ capabilities, we excel in precision cutting of shapes and nests with no mechanical stress, heat distortion, or heat-affected zones in the cut metal. We offer:

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal capability

- 4000mm x 2000mm bed

- Up to 200mm thick

- In-house qualified engineering support

- Qualified in-house CNC programming

- CNC-controlled

- Complex shape-cutting

- Dramatic improvements in material utilisation

- Electronically-controlled Dot Peen hard stamping

- Full lot traceability

We operate automatic and semi-automatic circular saws and band saws enabling ultimate flexibility when cutting any metal in any quantity. Tubes and extrusions can be supplied cut in half to make handling easier, cut to matrix (full lengths cut to an equal length multiple) or cut into pieces. With multiple saws offering various capabilities we provide:

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal capability

- Up to 400mm diameter

- Precision cutting to length of thin-wall tubes and extrusions

- Cutting tolerances of +/- 1.0mm

- Deburring

- Custom packaging to customer needs

- Full lot traceability

We are equipped with numerous CNC machining centres in our modern machine shop facilities and provide the following services:

- In-house qualified engineering support

- Qualified in-house CNC programming

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal capability

- Surface milling

- Drilling,tapping and counter-boring

- Profiling

- Rough machining and pocketing

- Full billet preparation

- Nesting facilities to reduce lead times and maximise material utilisation

- Electronically controlled Dot Peen hard stamping

- Full lot traceability

Metal turning is a form of machining. It is a material removal process used to create cylindrical parts using a turning machine or lathe. We operate both manual and CNC-controlled machines to produce turned parts. Our turning capabilities include:

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal

- Up to 300mm diameter

- In-house qualified engineering support

- Qualified in-house CNC programming

- Electronically controlled Dot Peen hard stamping

- Full lot traceability

- Custom packaging to customer needs

Boring machining is a common process used to create holes of varying sizes. The boring process is used to enlarge a hole that has been previously drilled out. Also known as internal turning, boring machining is ideal for cutting large-diameter holes with exceptional dimensional accuracy. We operate several modern machines to the diverse demands of our customers and are able offer the following:

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal capability

- From 50mm – 300mm diameter

- In-house qualified engineering support

- Qualified in-house CNC programming

- Electronically controlled Dot Peen hard stamping

- Full lot traceability

- Custom packaging to customer needs

Milling is a general term for machining processes used in manufacturing to remove material from the starting metal using rotary cutters. We operate several modern CNC machines to produce to the varying demands of our customers and can offer the following:

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal capability

- Milling tolerances of +/- 0.2mm

- In house qualified engineering support

- Qualified in house CNC programming

- Horizontal milling

- Vertical milling

- Electronically controlled Dot Peen hard stamping

- Full lot traceability

- Custom packaging to customer needs

Trepanning is a deep-hole drilling process. The practice is typically used on larger diameter bars when the drilling process leaves a core; the solid core may then be used on other orders. We operate a number of modern machines to produce to the varying demands of our customers and can offer the following:

- Aluminium, steel, stainless steel, titanium, nickel alloys and yellow metal capability

- From 50mm – 300mm diameter

- In-house qualified engineering support

- Qualified i- house CNC programming

- Nesting facilities to reduce lead times and maximise material utilisation

- Can dramatically improve material utilisation

- Electronically controlled Dot Peen hard stamping

- Full lot traceability

- Custom packaging to customer needs